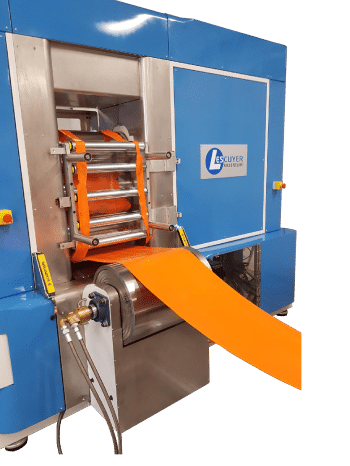

3 cylinders calenders

Innovative design - Optimized safety and precision

Lescuyer’s 3 cylinder electric calenders are the fruit of many years of R&D. In fact, this model is the result of an innovation project accredited by the Elastopôle cluster to meet the new NF EN 12301 safety standards of 2016. In the safety phase, the maximum distance between cylinders must be 50 mm.

The calendering unit is monobloc and fully encapsulated, making it highly adaptable to medium-sized production industries. The gap between each roll is motorized, for optimum control of product thickness at the calender outlet. The temperature of each roll is controlled via the operator console. Our technology enables us to achieve a high level of precision on plates produced at speeds of up to 25 m/min.

All Lescuyer calenders comply with the highest safety standards: NF EN 12301 and directive 2006/42/CE.

Features

- Meets the most stringent safety requirements

- Optimum temperature control

- Micrometric sheet thickness accuracy

- Strip scrap recovery system

Turnkey equipment with delivery, installation and training of on-site teams.

Numerous options can be added to Lescuyer roll calenders, such as cooling rollers, thickness control by Laser probes and consequent servo-control of roll gap, automated cutting accessories at the output, etc.