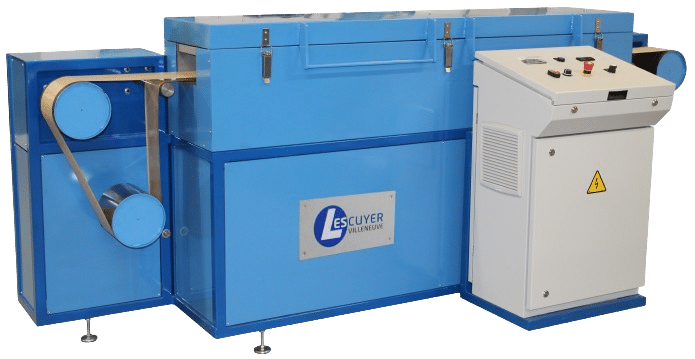

Vulcanization equipment

The optimum vulcanization solution for all product types

Lescuyer et Villeneuve offers a range of vulcanization systems to suit your specific needs, depending on the material type, geometry and line speed. Our infrared shock modules stabilize the profile for the rest of the process without noticeable deformation, by heating up to 700°C for a short, non-contact period

Lescuyer UHF microwave ovens can be used to preheat large cross-section products, whether single or multi-material, compact or expanded. Operation is optimized by the high density and efficiency of the generators. Our hot-air ovens maintain product temperature thanks to 2-meter modular elements

All our vulcanization systems comply with the highest safety standards

Features

Lescuyer et Villeneuve offers an exclusive salt-bath vulcanization process using MDC Engineering‘s innovative, world-renowned LCM VulcanoClean technology. The technology is an ecological innovation that recycles salts and treats fumes and washing water in a closed circuit

Turnkey equipment with delivery, installation and training of teams on site

A start-up service is also available, enabling lines to be optimized thanks to the experience of our teams